Maid to Order

By Christopher Roy, Senior Staff Writer

Take one newly built world-class passenger vessel, purposely divide it into 16 pieces and reassemble. Does this sound like the recipe for a make-work project? Perhaps, but due to unique circumstances, these were the conditions that John TG Vickery, president of Vickery Electric, a Whitby, Ont.-based electrical contracting company, faced while installing the electrical system on The Maid of the Mist VII tourist cruise boat.

With a varied history in the marine industry, including new-ship construction, retrofits, and Canadian Coast Guard electrical-inspections and repairs, Vickery Electric has wired tugboats, dredges, automated scows and other marine vessels since 1950.

The Maid of the Mist Steamboat Corporation, impressed with Vickery’s three generations of ship building electricians, requisitioned them to install the electrical system on the newly designed Maid of the Mist VII. Although marine construction accounts for almost 30 per cent of his annual business, John Vickery had never encountered a project where the ship was to be constructed, disassembled only to be re-built and rewired.

The Maid of the Mist cruise line offers its passengers a unique and thrilling trip to the base of the powerful Niagara Falls. The vessel navigates against the current, so close to the waterfalls that its passengers wear raingear to avoid being drenched.

From an electrical standpoint, Vickery had to wire a system that would provide the required power to safely maneuver the cruise boat and its 580 passengers under such extreme conditions.

From an installation point of view, the project presented another interesting twist. The newest version of the Maid of the Mist series was to be constructed in a shipyard located in Belleville, Ont. and then dissected into sixteen pieces for transportation to the gorge at the base of the falls. With whirlpool rapids at one end of the gorge and the Niagara Falls at the other, it’s impossible for any ship of such size to nautically enter the waterfalls’ base, the vessel’s docking destination. The boat had to be shipped piece-by-piece on a bed of transport trailers from the shipyard across the province to the limited parking lot area in Niagara Falls, where it would be reassembled — a construction project that in terms of labour amounted to two time the work. Vickery had to plan the installation so that it need only be wired once.

The process began with a series of meetings with the contractor Cartier Construction, the Maid of the Mist Steamboat Corporation, and the marine naval architect. With construction about to begin, the electrical drawings and specifications were not to-hand. The design and construct relied on the customers’ electrical requirements and the power of the equipment to be used on the vessel.

“Because the ship is confined to a secluded body of water and operates strictly in daylight, it does not require radar or running lights.” said then Cartier project manager, now general manager of marine operations for the Maid of the Mist Corporation, Emil Bende. “That reduced the number of electrical systems for the ship considerably.”

Using the marine naval architect’s drawings, Vickery’s design of the electrical systems needed continual approval from the Coast Guard “They stop-by on an on-going basis,” said Vickery.

A 100 amp 120/240 single-phase service had to be installed in a limited area which demanded that Vickery’s electrical-cabinet building department construct the main control cabinet from scratch. The transfer switches, dc panels, the steering system and adjustments to the electrical distribution panels were actualized from the ground up in the shipyard.

“There were time constraints because the company did not want the business operation to be disturbed for too long.” said Bende. “Time on the job was critical for all involved. You did as many things ahead of time as possible.”

“With the dissection of the vessel, we needed to look at each specific area to completely pre-wire it,” said Vickery. “The sections were divided by the main contractors. Each segment of the vessel that could be pre-wired was, and the cables were coiled and labeled in Belleville.”

The interior lights, motor controls and receptacles were all in place ahead of the move to Niagara Falls. After the vessel’s re-assembly at the Gorge, the wiring could be done through simple identification of the proper junction boxes and points of connection.

Any wiring that required integral cross-section cabling was left to be done in the limited time-window at Niagara Falls. A section of ladder tray was installed in a central piece of the disassembled boat to aid with the hookup-connecting the wheelhouse and the engine room. Because of the considerable amount of wiring needed to connect the bow (where the wheelhouse is kept) to the stern (where the engine room is located), pre-wiring of all cross-sectional systems, such as the indicating lights and the bilge water level systems, were left until after the boat was reassembled at the gorge.

Several hundred thousand gallons of water pour over the Falls and slam into the Niagara Gorge ever second — cruising only meters away from some of the most turbulent waters in the world, the need for reliable steering control of the Maid of the Mist is crucial.

The complex steering system could also only be installed in Niagara Falls. It required the installation of a series of four separate back-up systems, each capable of returning the boat to the dock. For safety measures each of the two rudders were wired to the generator power system and its dc backup system. Barring the loss of all power in those systems, two independent batteries were installed, one for radio and lights and the other for the steering system, to assure the safe deliverance of passengers back to shore. Vickery had worked on the design and construction of the unique control system that would allow the vessel to operate safely even under extreme conditions. “The Maid of the Mist Corporation demands significant quality,” said Vickery, “and safety was always the key factor.”

Following the completion of the vessel’s electrical installation in the parking lot, a shore side safety and system verification of all systems were proven, and the Maid of the Mist VII was put through a final series of sea trials under the vigilant eyes of the Coast Guard. All areas (including the electrical systems) were tested and verified with the minor problems corrected by John Vickery. After the construction, deconstruction, and reconstruction, the Maid of the Mist VII was given its sailing papers.

Hundreds of thousands of tourists from around the world flock to see Niagara Falls each summer. Many of this years’ visitors will be able to don the rubber hats and raincoats, climb aboard the Maid of the Mist VII and taste some of Niagara’s spray, all because of the work of people like John Vickery. Few if any will ever know the momentous work that went into making the Maid seaworthy or ever hear the vessel’s Humpty Dumpty-like origins.

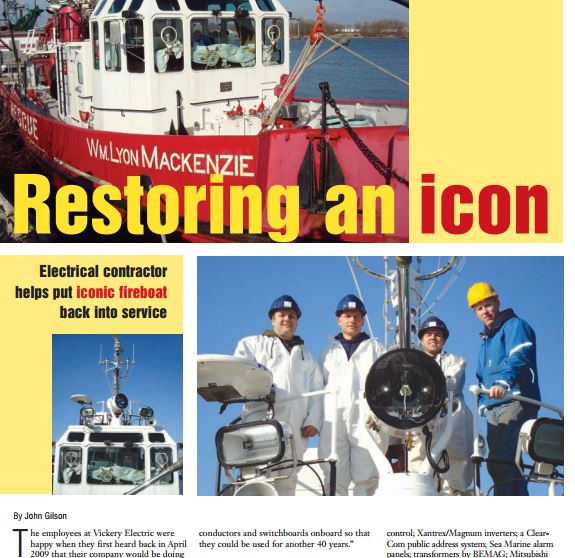

Restoring An Icon

The employees at Vickery Electric were happy when they first heard back in April 2009 that their company would be doing an electrical retrofit of the William Lyon Mackenzie, a fireboat operated by Toronto Fire Services.

source: http://www.ebmag.com/images/stories/PDFarchive/2010/04ebmagmay2010.pdf